Tata Group companies quietly partner with Elon Musk-led Tesla; become global supplier to EV maker – The Times of India

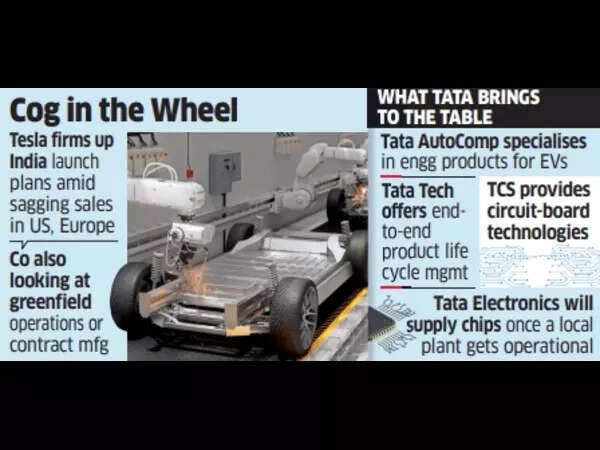

Several Tata Group companies have silently established themselves as global suppliers to Elon Musk-led Tesla, which represents approximately half of the global automotive industry’s market value. These companies – Tata AutoComp, Tata Consultancy Services, Tata Technologies, and Tata Electronics – are positioning themselves for expanded opportunities should Tesla establish operations in India.

These Tata Group companies have reportedly secured global agreements with Tesla as essential partners in their supply chain network. They contribute to the approximately $2-billion worth of Indian supplies to the American electric vehicle manufacturer in FY24. Tesla has initiated conversations with existing suppliers about the possibility of establishing facilities near their manufacturing centres to enhance the supply ecosystem.

“Tesla is, in a way, readying the supplier base in India,” a top industry source told ET, requesting anonymity. “We are very sure that once Tesla starts manufacturing here, Indian suppliers will benefit from sourcing opportunities.” Senior procurement executives from Tesla have reportedly held meetings with numerous current suppliers.

These discussions have centred on the potential development and production of various components, including castings, forgings, electronics, and fabrication items.

Tesla tie up with Tatas

Currently, India serves primarily as a development and supply hub for Tesla’s operations. According to sources, Tesla intends to procure various components from suppliers outside China and Taiwan. These include wiring harnesses, electric motors, gearboxes, forged components, castings, sheet metal, sophisticated electronics, suspension systems, electric powertrains, and ball and ceramic bearings. Within the Tata ecosystem, AutoComp provides specialised EV engineering products, whilst Tata Technologies delivers comprehensive product lifecycle management services. TCS supplies circuit-board technologies, and Tata Electronics will provide chips once a manufacturing facility becomes operational.

Whilst these Tata enterprises maintain their current global supply arrangements, their future strategic decisions may be influenced by Tesla’s ultimate choice regarding local manufacturing or contract manufacturing for the Indian market, the financial daily’s report said.

Also Read | Elon Musk’s Starlink may offer 80-90 times more than capacity of rivals Reliance Jio-SES, Eutelsat OneWeb

Tax advantages and financial incentives are key factors in Tesla’s strategic planning for its Indian market entry. The company is carefully evaluating potential duty exemptions and special provisions. Officials familiar with the situation note that Tesla maintains strict confidentiality agreements with suppliers regarding component origins and sourcing locations.

Tesla is likely to source essential vehicle control components from Tata Electronics, including printed circuit board assemblies for Tesla’s battery management systems, motor controller units and door control mechanism, the ET report said.

Tesla has established partnerships with numerous Indian manufacturers, including prominent names such as Samvardhana Motherson, Suprajit Engineering, Sona BLW Precision Forgings, Varroc Engineering, Bharat Forge, and Sandhar Technologies, for sourcing vital components.

The financial value of these Indian-sourced components has reached a significant level, estimated between $1.7-1.9 billion during FY24. Industry analysts note that this procurement from Indian suppliers has further increased in FY25.

Also Read | ‘Elon Musk doing amazing work, but…’: Why Sajjan Jindal believes Tesla won’t find it easy in India

Following the supply chain challenges during the Covid-19 crisis, Tesla has implemented a strategy to reduce its dependence on China by sourcing electronic, electrical, and mechanical components from alternative locations.

While Tesla produces certain essential electric components internally, including electric motors, battery packs, and chargers, it depends on international suppliers for various subassemblies and components. The company traditionally maintains strict privacy regarding its supplier associations.

The electric vehicle manufacturer has instructed its suppliers serving markets outside China to establish production facilities beyond China and Taiwan’s borders, with implementation expected from next year.

The company is currently engaged in discussions with multiple Indian states, including Rajasthan, Gujarat, Tamil Nadu, Maharashtra, and Telangana, regarding the establishment of manufacturing facilities in India, according to sources. The initiative aims to bolster the company’s presence whilst creating additional prospects for Indian suppliers.